The spring that forms the main drive mechansim of the flexDrive is cut from a thin piece of spring steel (Blue-Finished and Polished 1095 Spring Steel .002" Thick, we buy from McMaster) using a wire EDM process.

Design files on github

Cutting springs with wire EDM

...

We've been using Jack's Machine Shop as our supplier in the U.S (They won't ship outside the US, if you are aware of a machine shop located outside the US, especially one in the EU, please get in touch with us!). The last time we ordered from them, they charged $11.00 per piece for a quantity of 100.

Design variants

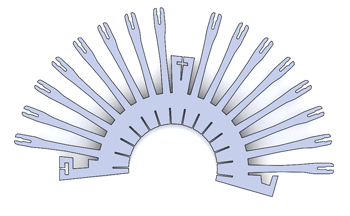

Early springs with wide heads vs updated thinner ones

Varitn there's multiple designs, early springs with wide heads (v1.0), these work well but the heads of the springs are a bit too wide and can intresect. To avoid this, simply cut the sides of the heads down with scissors. It might even be useful to remove one of the sides of the head.

The updated thinner design (v1.1) doesnt have this issue because the heads are much less wide.

We have variants with kerf adjustment already taken care of, for a kerf of 13mil/0.33mm, or a variant which represents the desired final part dimensions, in which kerf needs to be adjusted for.