6 - Shielding the drive

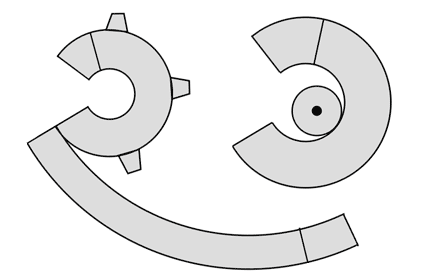

Attaching the housing/shield

Use plain transparency sheet for the cap part.

Clamp the parts with a hemostat while the epoxy cures.

Guide the ground wire through the bottom opening of the protective shield cone and attach cone with epoxy. Make sure there is a strong bridge of epoxy between the side of the drive body and the cone. Use multiple layers of epoxy if needed. Take extra care not to touch and bend electrodes with the protruding end of the ground wire.

Apply small amount of mineral or silicone oil to the springs where they meet the screws.

At this point the electrodes can be lowered somewhat and gold-plated if desired. After gold-plating and impedance measurement, the gold pins should be secured to the eib with a thin layer of 5-minute epoxy. Use a thin wire or similar tool to distribute the epoxy between the pins so it makes good contact with the EIB and the pins, otherwise its possible that the epoxy stays on top of the pins and tetrode stubs, especially on the dense small 64ch EIBs. When re-using the EIB for another drive later, this epoxy can be removed easily by leaving the EIB in ethanol for a few days. This softens the epoxy so it can be easily removed. Also make sure to remove the epoxy from the omnetics connector(s), also under the solder feet, and re-epoxy the connector.

The drive is now ready to implant.