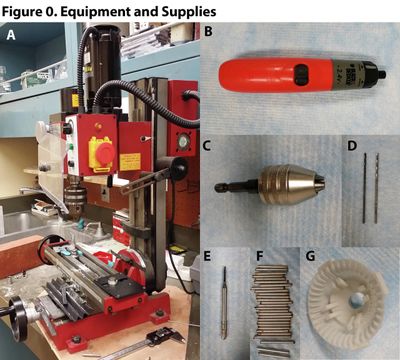

Procedures

The drive core holes must be cleaned and tapped, and the guide tube sleeves must be inserted, before the drive core is mated with the targeting cone.

- Drill outer ring of holes for shuttle bolts (FIg. 1A). Mount the #57 (.043") drill bit in the drill press, and turn it on at a LOW rotation speed (high speed will melt the nylon of the drive core and distort the holes). Gently run the drill bit through each of the outer holes in the probe shuttle bays.

- Drill inner ring of holes for guide tube sleeves (Fig 1B). Mount the #56 (.0465") drill bit and turn on the press at a LOW rotation speed. Gently run the drill bit through each of the inner holes in the probe shuttle bays.

- Tap outer ring of holes for shuttle bolts (Fig 1C). Mount the multipurpose chuck in the electric screwdriver, then mount the customized 0-80 tap plug in the chuck. Carefully align the tap plug to be perfectly parallel with one of the shuttle bolt holes by laying the tap plug into the shuttle bay. Press the tap plug gently into the hole, and start the electric screwdriver to screw in the tap plug and tap the hole. When the tap plug has passed all the way through the length of the hole, reverse the direction of the screwdriver to remove the tap plug from the hole. Repeat for all of the shuttle bolt holes in the Drive Core.

- Insert guide tube sleeves (Fig 1D), Align a guide tube sleeve to be perfectly parallel with one of the sleeve holes in a shuttle bay. Gently push the sleeve all the way into the hole. If necessary, you can use a point-ended tool to push the sleeve into the hole. Repeat for all of the guide tube sleeve holes in the Drive Core that will be used.